Gas Cylinder (Fire Cylinder) Testing and Filling Services

Gas Cylinder Inspection and Filling Services

- fully qualified

- Perfect service

- industry expert

Jian'an Firefighting-Gas Cylinder Inspection and Filling Specialist

Professional Customization, Intelligent Guarantee

In the field of gas cylinder testing and filling services, with the professional strength of full qualification, we provide customers with complete services and a large number of cases of high-quality filling services. Our professional team has been working in the industry for many years, and is not only proficient in all kinds of gas cylinder testing and filling technology, but also able to provide professional and customized filling services according to the specific needs of different customers.

At Jian An Fire Protection, we understand the importance of gas cylinder safety to fire safety management, so we strictly follow the relevant national safety technical regulations to ensure that every service meets the highest standards. Our service process covers from the appearance inspection of gas cylinders, parts inspection, hydraulic test, gas tightness test, to the final agent filling and re-confirmation of the gas tightness, each step of the process strives to be precise and efficient.

The use of gas cylinders is ubiquitous in industry and firefighting. From oxygen and firefighting cylinders to LPG and acetylene cylinders, these cylinders provide essential gases while posing potential safety risks. Therefore, testing and filling services for gas cylinders have become crucial.

Gas Cylinder (Fire Cylinder) Maintenance Frequently Asked Questions

Frequently Asked Questions I

Reduced pressure in the storage bottle group causes the extinguishing agent not to be sprayed normally and hinders the extinguishing efficiency when a fire occurs.

Frequently Asked Questions II

The inner wall of the bottle corrodes and thins, and the agent leaks, resulting in the inability to properly extinguish fires and a serious risk of explosion.

Frequently Asked Questions III

Rusting on the outside of the bottle and thinning of the wall thickness results in a risk of leakage and explosion of the gas cylinder, which can seriously lead to casualties.

The Importance of Regular Fire Cylinder Testing

Firefighting gas cylinders are an indispensable part of the fire safety system, and they usually contain extinguishing agents, such as Heptafluoropropane, Carbon Dioxide or IG541 mixture, which are used to quickly control the fire in its early stages. According to the "Regulations on Gas Cylinder Safety Technology Supervision" issued by the General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ), firefighting cylinders must be tested every three years, while nitrogen cylinders are tested every five years. These regulations are designed to ensure the safety and reliability of gas cylinders and to prevent potential hazards caused by aging or damaged equipment.

National testing regulations

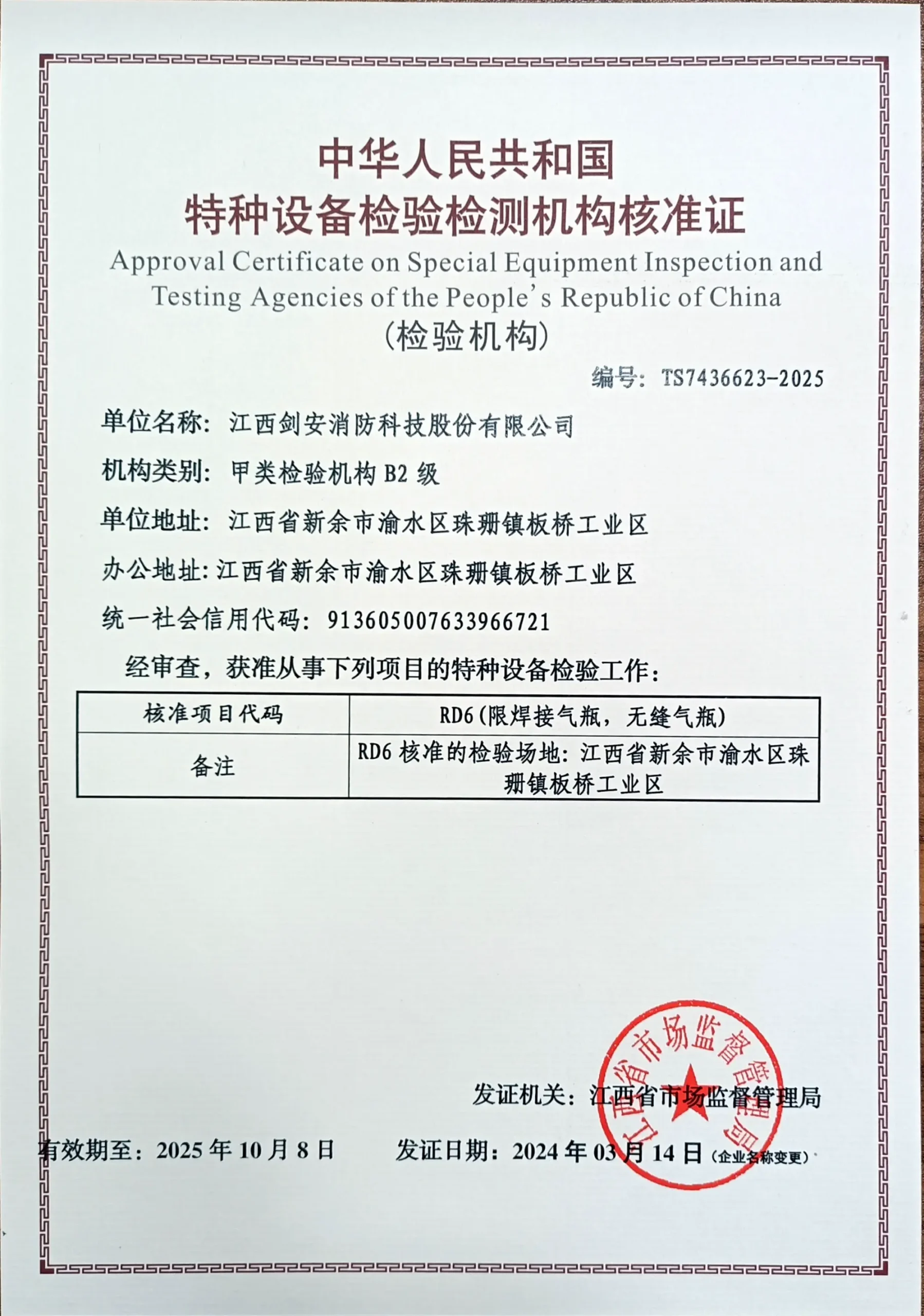

- Rules for Approval of Special Equipment Inspection Bodies TSG Z7001-2021

- Technical Regulations for Gas Cylinder Safety TSG 23-2021

- Safety Technical Supervision Regulations for Fixed Pressure Vessels TSG 21-2016

- Technical Conditions for Gas Cylinder Inspection Organizations GB/T 12135-2016

- Regulations on the Safety Supervision of Special Equipment State Council Decree No. 549

- Special Equipment Safety Law of the People's Republic of China Presidential Decree No. 4

These regulations provide guidance on the legal and technical aspects of the testing of gas cylinders to ensure standardization and normalization of testing.

Firefighting Cylinder Inspection and Maintenance Methods

According to "Gas Cylinder Safety Technical Regulations TSG23-2021", the gas fire extinguishing system extinguishing agent heptafluoropropane, high-pressure carbon dioxide, IG541 Test filling every three yearsNitrogen cylinders are tested and filled every five years.

- The fire extinguishing agent storage bottle is weighed and inspected once a year, and if the weight of the storage bottle decreases by more than 5%, the storage bottle must be refilled or replaced.

- Regularly no less than once a quarter to check the pressure gauge, the pointer beyond the green zone or after use should be entrusted to the manufacturer or trained and qualified to install the fire engineering unit for maintenance.

- Every 5 years on the storage bottle for a hydrostatic strength test, the pressure is 5.3MPa, qualified to continue to use, such as corrosion, the storage bottle should be a rust treatment. At the same time of checking the storage bottle, all the valves for a strength hydrostatic test, the pressure is 5.3MPa.

- Welded cylinders are full according to the regulationstwenty yearsMandatory scrapping, seamless cylinders have also been changed to full according to the regulations.twenty yearsMandatory scrapping.

Jian'an fire gas cylinder testing and filling process

1

Bottle valve disassembly

2

hydraulic pressure test

3

Gas cylinder drying

4

Bottle Valve Overhaul

5

Pharmaceutical filling

6

air tightness test

7

Pending shipment area

Cylinder testing and filling process description

1. Preparation before testing

Customer site survey: conduct a professional survey of the customer's site and propose an overall solution for gas cylinder disassembly, testing, filling and installation.

Fire alarm lifting: the person in charge of construction and the main construction personnel to the site to clarify the technical requirements of construction, the solenoid valve on the wiring removed, the host, such as alarm, press the mute button.

2. Gas cylinder equipment disassembly and transportation

① Remove the starter bottle (or active bottle) starter brass nut, starter bottle solenoid valve and wiring, and starter line in order;

② in order to remove the high-pressure hose, pilot valve, put on the cylinder head cap, remove the cylinder clamp, remove the cylinder, and dismantle the equipment uniformly according to the location specified by Party A standardized placement;

③The plane handling process should be carried out using a special cart for cylinders, and the cylinder equipment is bundled and packed in groups on wooden pallets;

④ Keep the cylinder head valve protection cover intact to prevent accidental spraying during unloading and handling;

⑤ Arrange for forklift drivers to unload the goods and place a flat surface to prevent the goods from tipping over.

3 . Firefighting cylinder testing and filling process

①Bottle valve disassembly; ②Hydraulic pressure test; ③Cylinder drying; ④Bottle valve maintenance; ⑤Pharmaceutical filling; ⑥Gas tightness test; ⑦Delivery area

4. Archiving of information

Fire gas cylinder testing and charging data archiving: after the end of testing and charging, provide fire gas cylinder periodic inspection report, list of qualified cylinders for periodic inspection, fire extinguishing agent charging record sheet, quality assurance certificate and other documents. Jian'an has done what work, the customer is clear, safe and secure.

5. On-site filling

On-site installation and commissioning acceptance: return the tested and filled cylinders to the site for installation, commissioning and acceptance. (e.g. Heptafluoropropane, carbon dioxide, IG541)

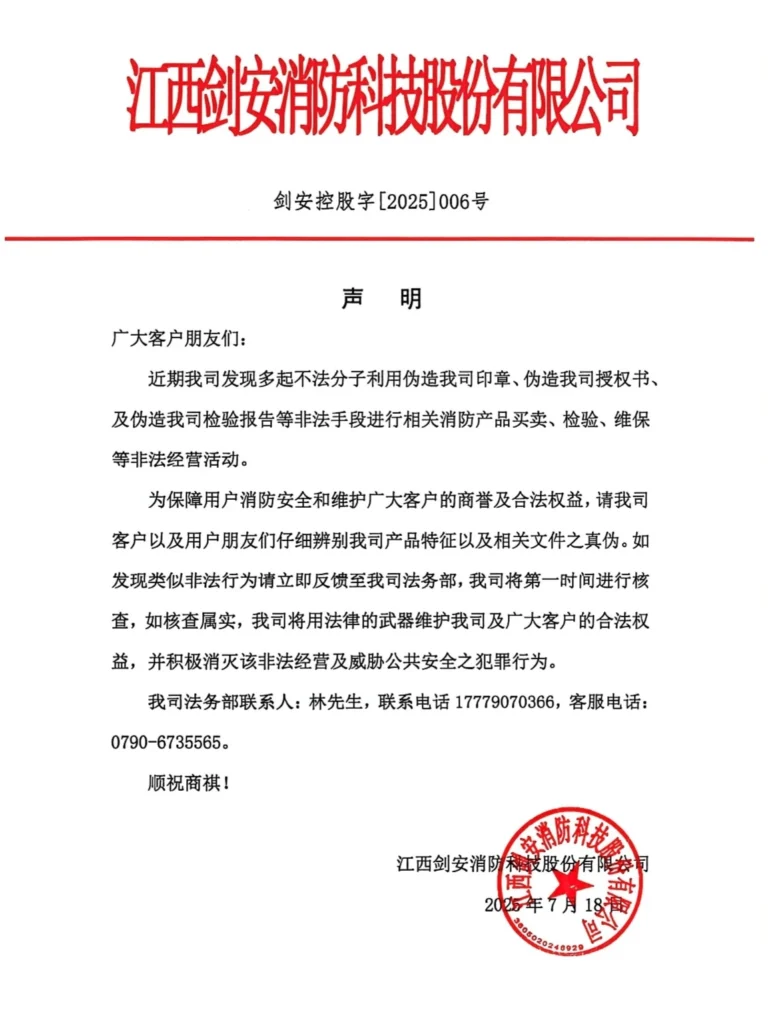

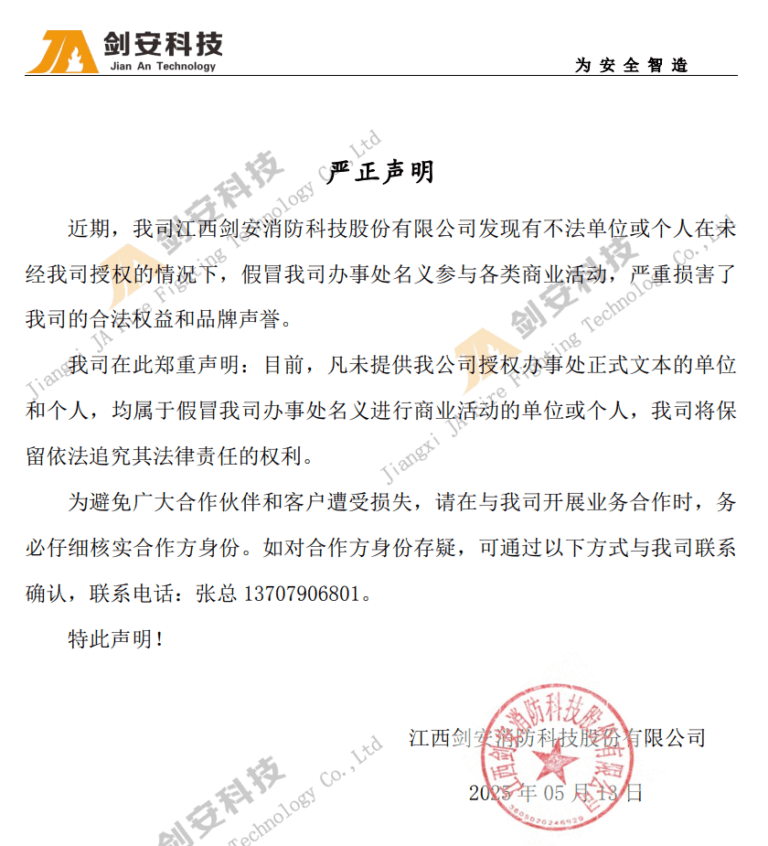

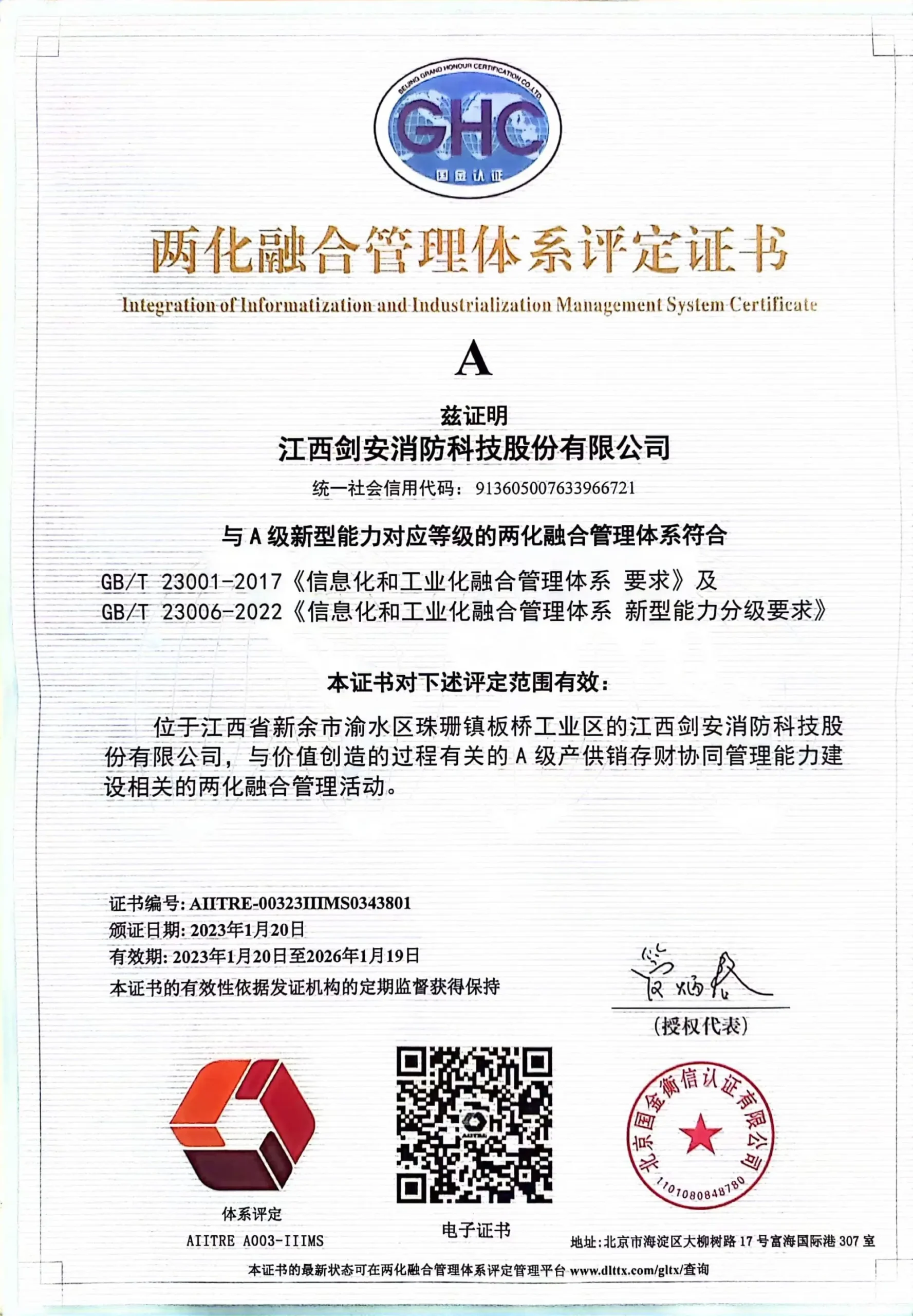

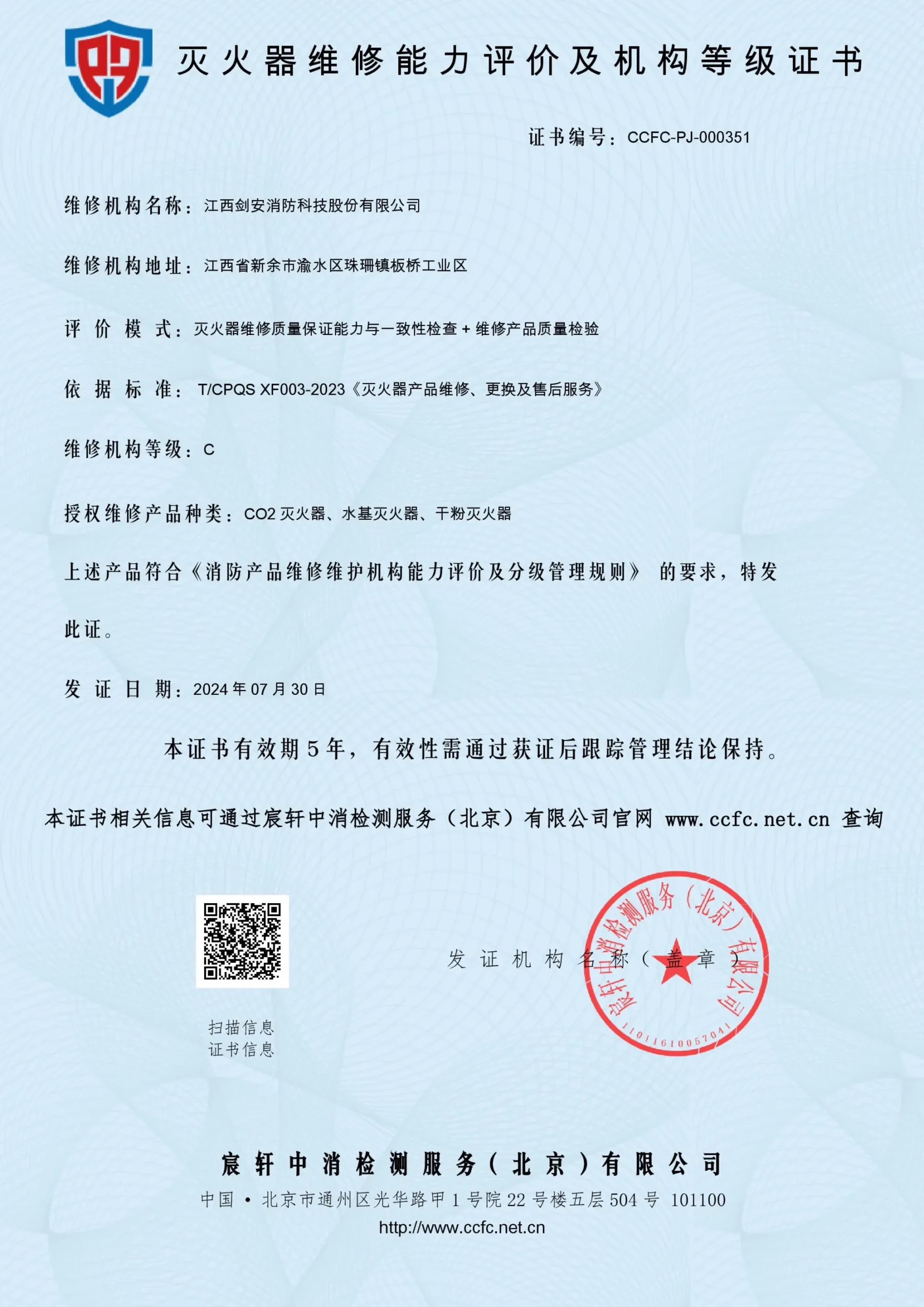

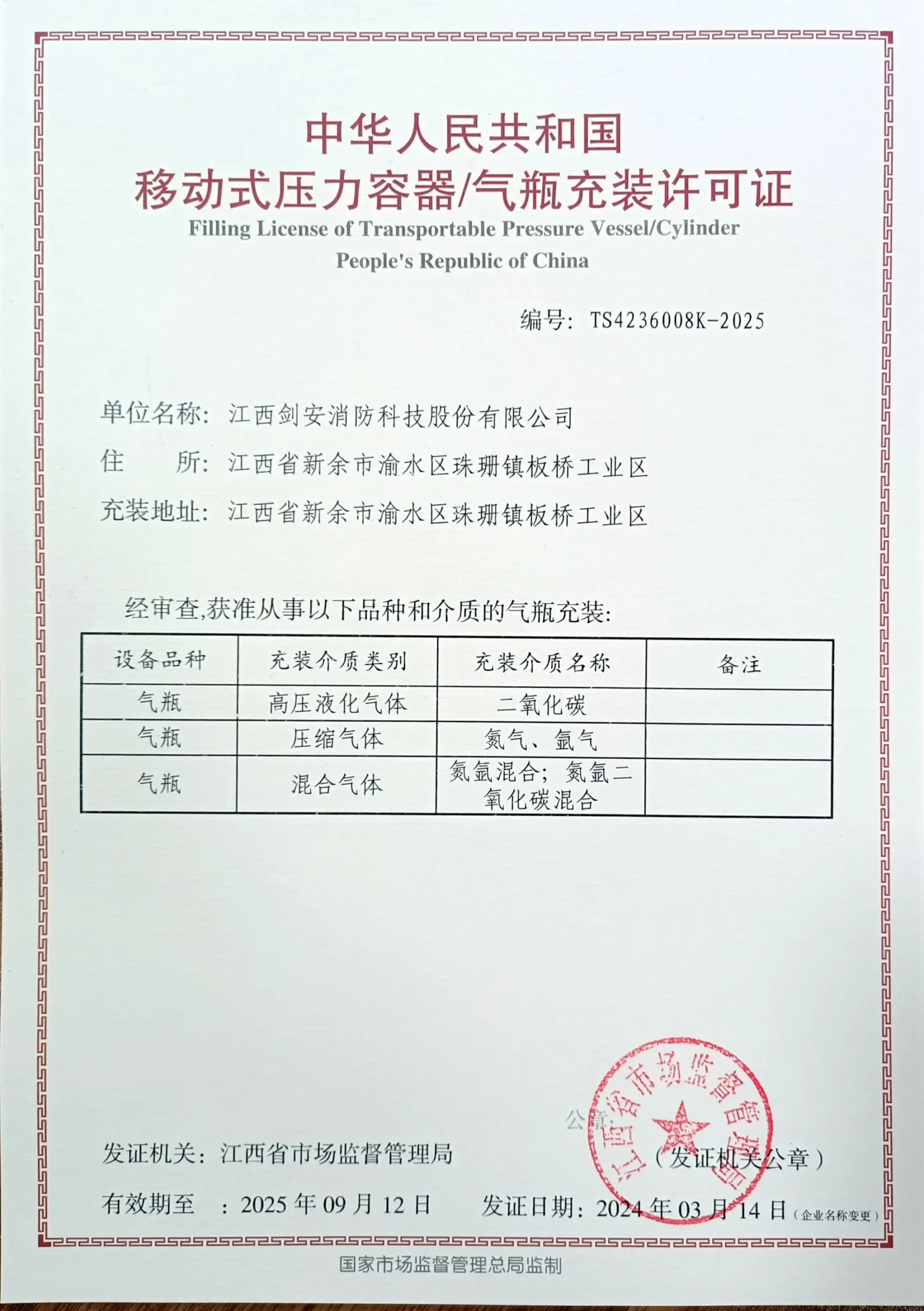

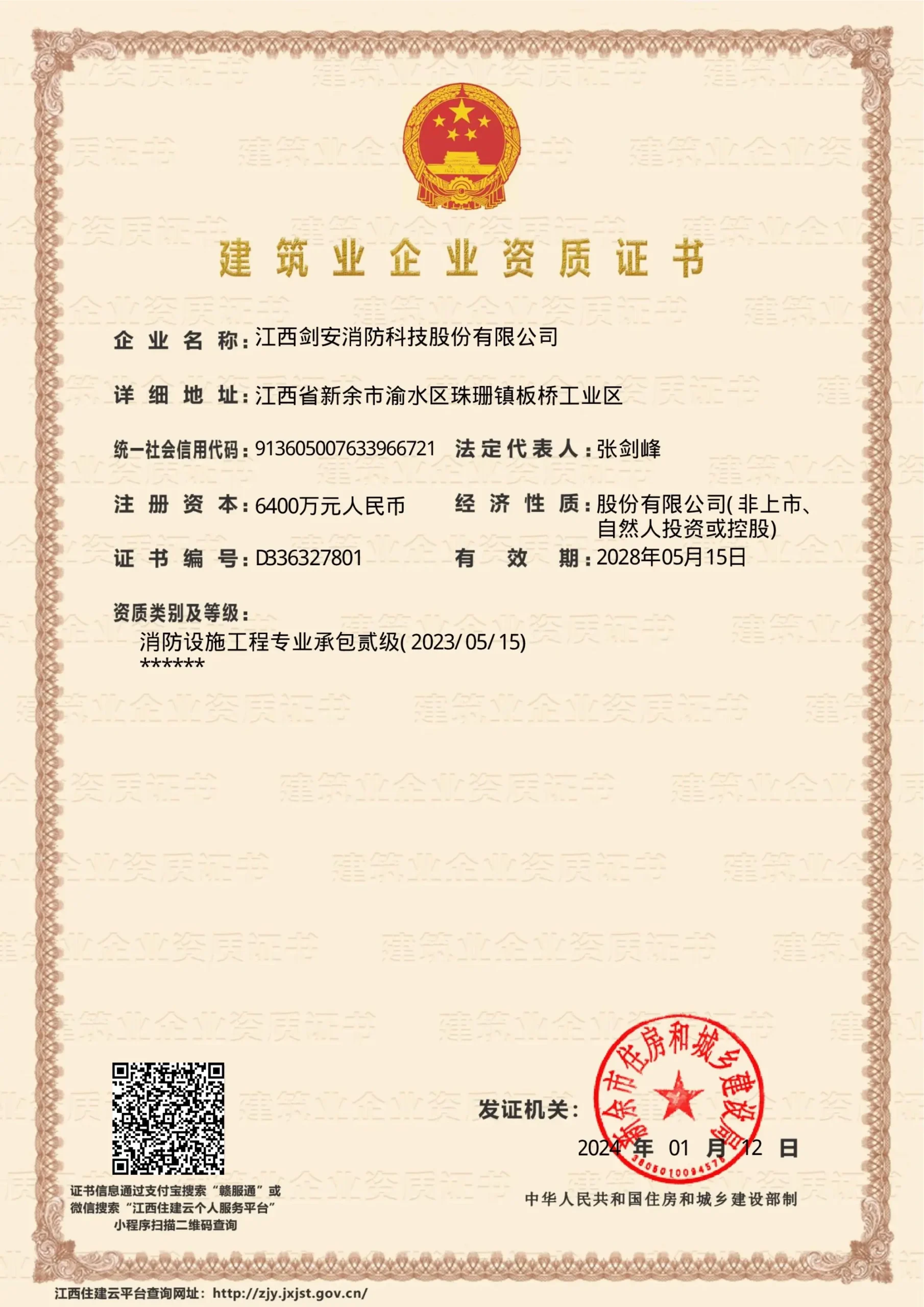

Fire Cylinder Testing Qualification

As an expert in the field of fire protection systems, Jian An has been in the fire protection industry for more than 20 years and is committed to providing the most advanced and reliable fire safety solutions. As a third-party testing organization with nationally recognized testing and filling qualifications, Jian An's independent testing services provide an additional safeguard for the safety of gas cylinders. By strictly following gas cylinder safety monitoring regulations, the safe use of gas cylinders can be ensured and the safety of personnel and equipment can be protected. Fire-fighting gas cylinders are dangerous goods, and according to Article 6 of the Gas Cylinder Safety Technical Regulations TSG23-2021, the inspected unit must obtain the appropriate qualifications approved by the market supervision department. That is to say, only with the corresponding qualification of gas cylinder inspection and testing, can we carry out gas cylinder maintenance. We, JD Fire Protection, have the inspection qualification of PD1 steel seamless cylinders and PD2 steel welded cylinders, and we can inspect and test the cylinders of Heptafluoropropane, IG541, and high-pressure carbon dioxide gas extinguishing system.

Gas cylinder testing and filling process need to use the equipment

High-pressure air compressor and electric hot water boiler

High-pressure air compressors play an important role in the cylinder filling process, providing stable pressure to ensure the efficiency and safety of gas filling. Meanwhile, electric hot water boilers are used to provide the necessary thermal energy to meet the filling needs of certain special gases.

Gas Detection Equipment

Gas detectors and gas analyzers are required Gas Detector: Used to monitor gas cylinder leaks to ensure that gas leaks are detected and acted upon at an early stage. Gas analyzer: to accurately analyze the composition and concentration of the gas in the cylinder.

Combustible gas detectors and laboratory fume hoods

Combustible gas detectors are used to monitor leaks from gas cylinders to ensure that gas leaks are detected and acted upon at an early stage. Laboratory fume hoods are used to provide a well-ventilated environment to prevent the build-up of harmful gases.

Lifting and hoisting equipment and gas cylinder cabinets

Lifting and hoisting equipment are indispensable tools for handling and positioning gas cylinders, they ensure the safety and stability of gas cylinders during transportation and use. They also need to be operated in accordance with gas cylinder safety monitoring regulations. Cylinder cabinets are specially designed for the safe storage of gas cylinders, which not only prevent them from being tipped over or struck, but also provide a range of safety measures.

Contact Us Now

If you have any questions or need assistance, please fill out the contact form to the right and a Jianan customer representative will contact you as soon as possible.

- Service Hotline: 400-915-1190

- E-mail:1013086865@qq.com

- Fax: 400-915-1190

- Address:Banqiao Industrial Zone, Zhushan Town, Yushui District, Xinyu City, Jiangxi Province, China

Online Message