Electrochemical Energy Storage Solutions

Electrochemical Energy Storage Solutions

- Strength Guarantee

- Quality Services

- Over 1000+ service cases

A fire safety bastion for electrochemical energy storage

Comprehensive solutions for electrochemical energy storage systems

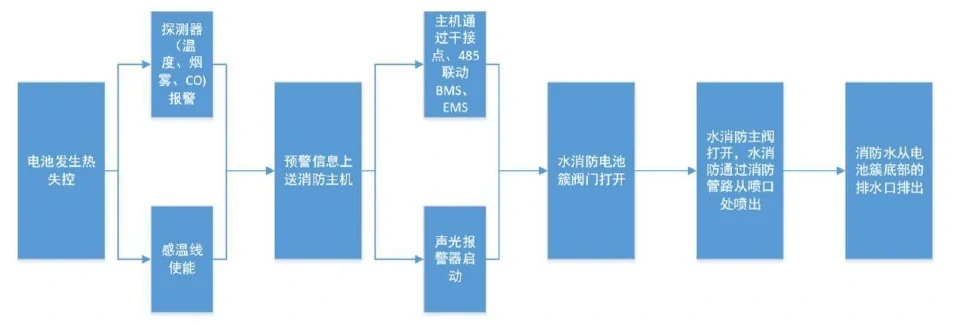

Jian'an provides comprehensive solutions in the field of electrochemical energy storage fire safety. As a professional organization that has entered the R&D and market application of energy storage fire protection technology earlier than others in the industry, Jian'an has realized a comprehensive coverage of fire safety solutions from front-end detection to back-end fire extinguishing. Based on the principle of "early detection and early disposal", the highly integrated fire detection device can provide early detection and warning for the primary stage of thermal runaway of lithium battery in the energy storage compartment.

The intelligent integrated device is capable of monitoring a variety of parameters such as hydrogen, carbon monoxide, VOC gas, smoke, temperature, etc., to monitor and analyze the characteristic quantities of thermal runaway of energy storage batteries in an all-round way. In addition, Jian'an Technology's solution also includes functions such as alarm signal acquisition linked with cabin detectors, activation of fire extinguishing devices, linked alarms, and linked communications with the BMS (Battery Management System) to suppress and deal with cabin fires with precise multiple spot spraying.

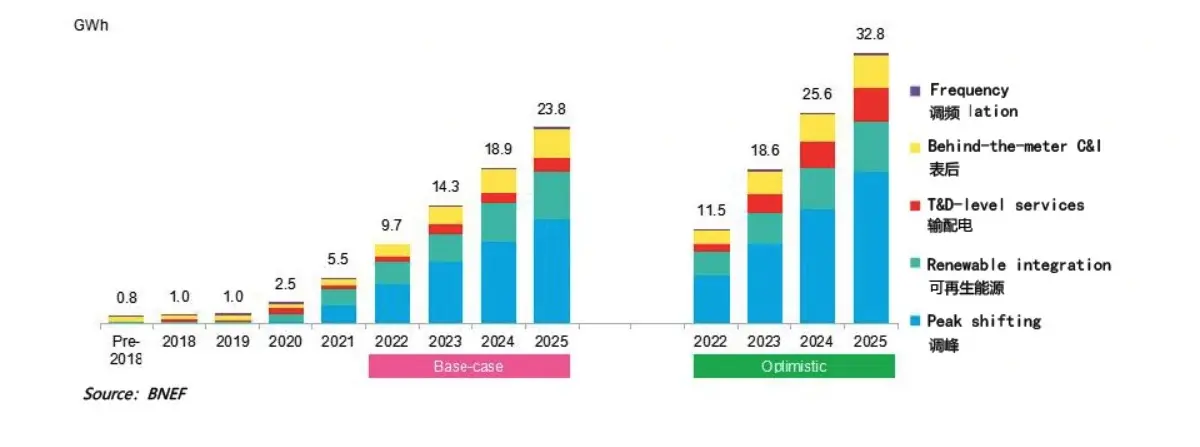

China Energy Storage Market Size Introduction

- In 2020, the global energy storage market new installed capacity of 5.3GW/10.7GWh, China's new energy storage deployment scale of about 1.2GW/2.3GWh, ranking first in the world.

- "During the 14th Five-Year Plan period, China's energy storage market is expected to grow more than tenfold, and BNEF forecasts that installed energy storage capacity will reach 10.3GW/23.8GWh (conservative estimate) or 13.9GW/32.8GWh (optimistic estimate) by 2025.

- Energy storage systems are mainly used in stand-alone peak shifting, renewable energy distribution and storage, grid transmission and distribution side applications, industrial and commercial applications, and frequency regulation applications.

Frequent energy storage accidents

- Between August 2017 and May 2019, South Korea experienced 23 energy storage plant fires, with frequent incidents forcing its energy storage projects to shut down for refurbishment.14 of the 23 energy storage system fires occurred after charging, six during charging and discharging, and three fires occurred during installation and construction.

- September 24, 2017 at about 11:29 am, South Korea Gangwon PyeongChang Tangyu Meitangmyeon Pingyong-ri (phonetic) wind power station's energy storage system fire of unknown origin, after 2 hours and 30 minutes to extinguish.

- On April 19, 2019, a fire and explosion at the 2MW/2.47MWh lithium-ion energy storage system at APS's McMicken substation in Surpise, Arizona, resulted in injuries to several firefighters and attracted a lot of attention.

- On May 17, 2021, an explosion occurred at the Beijing Jimei Home Dahongmen Energy Storage Power Station, which was likely caused by factors such as the safety and quality of the storage batteries, the battery management system, and the meteorological environment.

- According to incomplete statistics, more than 30 fire safety accidents of lithium-ion battery energy storage occurred worldwide in the past year, causing significant property losses. Therefore, after the cost of lithium-ion batteries has been reduced to the inflection point of commercialization, the fire safety of energy storage systems has become a key bottleneck restricting the large-scale promotion of lithium-ion battery power storage.

Energy Storage Laws and Regulations, Standards

national standard

GB 51048-2014 Design Code for Electrochemical Energy Storage Power Stations - A new draft has just been released for comment in the first half of the year.

group standard

T/CEC 373-2020 Technical specification for fire protection of prefabricated cabin type lithium iron phosphate battery energy storage power stations

T/CECS 10171-2022 Prefabricated Perfluorohexanone Fire Extinguishing Appliances

Technical Specification for Fire Protection of Lithium-ion Battery Energy Storage Systems, Requirements for Fire Early Warning, Prevention and Control System of Lithium-ion Energy Storage Power Stations-Chinese Engineering Construction Standardization Association Standards

local standard

DB11T1893-2021 Beijing Energy Storage Power Station Construction and Operation Code

Jiangsu power grid "on the issuance of prefabricated cabin type lithium iron phosphate battery energy storage power station fire technical measures (trial)" multi-provincial preparation of energy storage power stationFire Acceptance Criteria

DB37/T 3642-2019 Specification for the Design, Construction and Acceptance of Perfluorohexanone Fire Extinguishing Systems

Sectoral standards

National Energy Administration's Twenty-five Key Requirements for Preventing Electricity Production Accidents (2022 Edition) (Draft for Comment)

State Grid Equipment Department - Fire-fighting enhancement measures for electrochemical energy storage power plants

Reflections on energy storage fire protection systems

Fire protection systems for electrochemical energy storage systems

There are two main considerations for active fire design.

- One is to realize the parameter measurement of daily operation and maintenance of the battery through the battery management system to realize the identification of abnormal electrical parameters:- Signs of thermal runaway;

- Secondly, the prevention and control of fire is realized through thermal runaway early warning and fire-fighting equipment. Which is applicable to lithium-ion storage power station fire system should be developed and designed according to the fire characteristics of lithium batteries, in addition to effective linkage control with the battery management system.

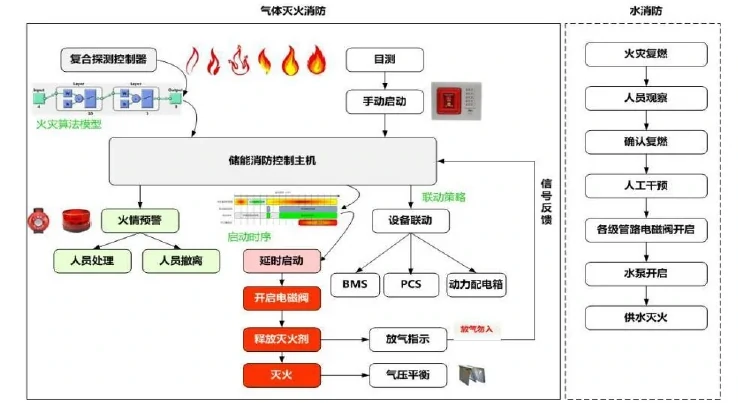

1, multilevel warning multilevel warning refers to the grading control according to the different severity of the battery thermal runaway, electrolyte leakage, the initial stage of the electrical fire, the battery heat spread, etc., which is convenient for operation and maintenance operations. The fire protection system of the energy power station needs to implement a hierarchical warning mechanism, using multi-level fire treatment and control to reduce the risk of widespread fire in the energy storage system, which can effectively protect the safety of the energy storage system.

2. Security linkage

- One is how to quickly and effectively detect the potential thermal accident and thermal runaway state of the battery, and take different warning messages (sound and light messages);

- Secondly, how to quickly activate the fire fighting facilities to realize effective fire extinguishing in case of thermal runaway.

- Third, the energy storage container internal signal, alarm, fault, action signal linkage, action signal is in the system there is a fire confirmation signal or fire extinguishing device is in an abnormal state (delay, start or bleed) linkage fire action relay, circuit breaker action, stop charging and discharging, with EMS and other control systems linkage.

- Addressing thermal runaway cascades in existing and operating systems, linkage control of ventilation and suppression; and

- Ventilation, fire suppression or cooling systems to manage thermal runaway in future energy storage facilities.

- Battery and battery storage system designs that slow down, or stop, cascading or propagation between cells and modules during thermal runaway.

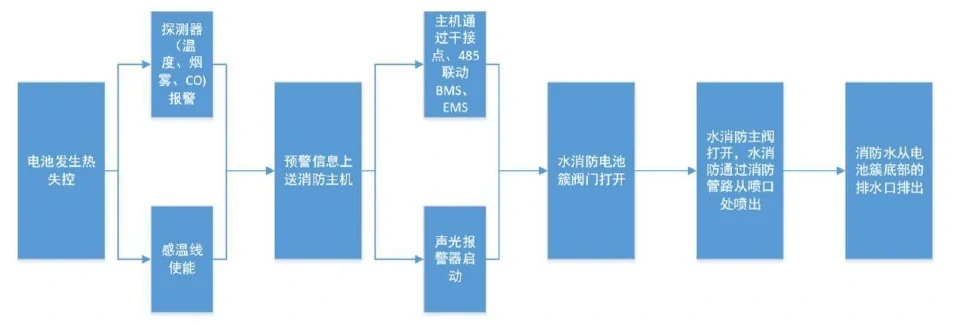

Solution Logic Diagram

JIANAN Technology Energy Storage Firefighting Total Solution

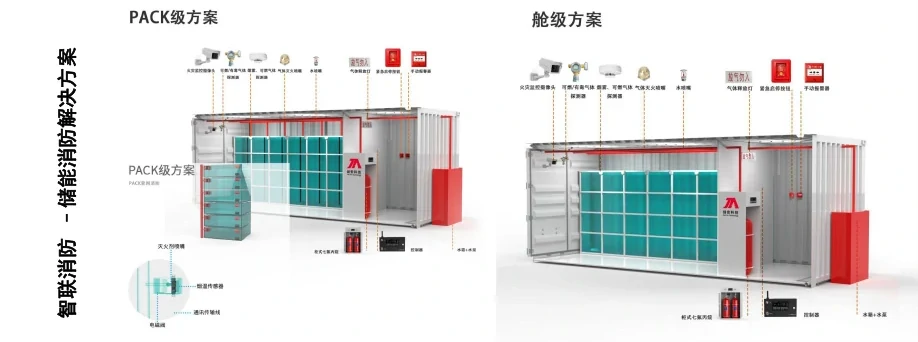

Jian'an Technology Energy Storage Fire Fighting Layout

Energy Storage Smart Fire Products and Configurations

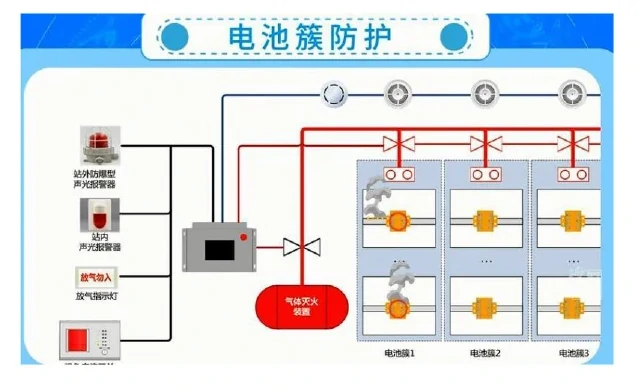

Jianan Technology Energy Storage Battery Family Protection Solution

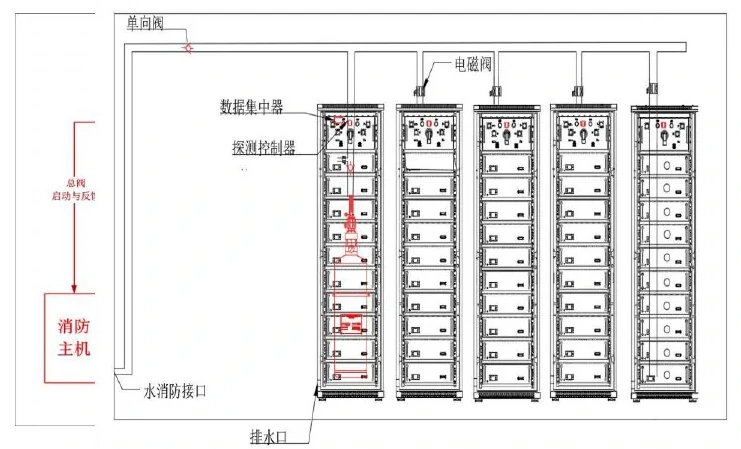

battery pack:: A detection controller is placed in each cell cluster, and a fire extinguishing agent and fire water connection is provided above the cluster body; a drain is provided below the cluster body; and a fire extinguishing agent tank is provided in one of the clusters.

piping (for water, oil, etc):: Transportation of fire-fighting chemicals and fire-fighting water, arranged as shown in the figure.

Detection Controller:: Real-time detection of the environment in the cluster and opening of the solenoid valve of the corresponding cluster when thermal runaway occurs.

Data Concentrator:: Receive telegrams from the detection controller to realize the control of fire extinguishing device activation, and forwarding data.

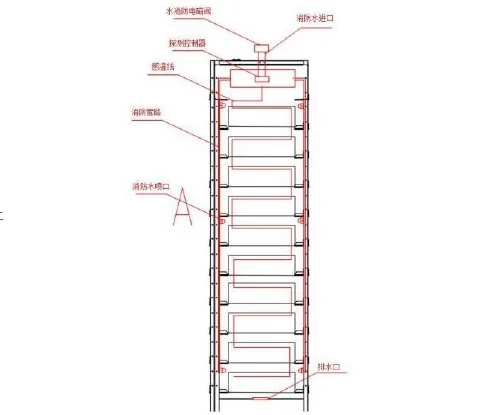

battery pack

The battery cluster adopts semi-closed structure, the fire extinguishing device is installed on the top of the battery cluster with hydrophobic cover plate between the battery boxes, and the bottom is equipped with drainage outlet.

Firefighting lines

Fire fighting pipeline is set up on the side wall of the battery cluster, the pipeline is connected to the top fire extinguishing device pipeline with a nozzle, and solenoid valves are set up in each battery cluster for individual control.

Detection Controller

Detection controller is set on the top of the battery cluster, the detector integrates smoke, temperature, C0, VOC sensors to detect the environment inside the cluster, and a temperature sensing line is set, the temperature sensing line passes through the inside of each battery box, and the opening of the cluster solenoid valve is realized by the detection controller of the box in which it is located.

Jianan Technology Energy Storage Battery Family Protection Solution

Jianan Technology Energy Storage Battery Family Protection Solution

Jianan Technology Energy Storage Battery Family Protection Solution

I. Factors contributing to the occurrence of fires in energy storage facilities (energy storage stations, charging piles, enclosures/cabinets, lithium batteries, etc.)

1, the battery system defects: such as the existence of battery polarity and cut off bad, bad active substance coating and other manufacturing defects are very likely to fire;

2. Poor shock protection system: Damage to the internal parts of the battery protection device will cause the DC contactor insulation to deteriorate and a fire will occur;

3. Inadequate management of the operating environment: such as moisture, powder rash, salt water and other environmental moisture intrusion into the battery system leading to melt traces and a decline in insulation performance and cause fire;

4, energy storage system internal energy out of control to produce high temperature caused by fire.

II. Fire-prone parts of the energy storage system

- Transformers and high-voltage switchgear: If the transformer unit is an oil-carrying device, the internal failure of the transformer unit will cause an arc heating, with the possibility of combustion and explosion;

- Low-voltage switchgear and control cabinets: Instability during charging, discharging and electrical energy output may be a fire hazard;

- power conversion system: There may be potential risks of overcharging and over-temperature during the conversion of the system;

- Battery matrix (stacks): Storage battery in the charging and discharging process of long-term operation of electrolytic water will produce a trace of hydrogen, if the indoor ventilation is not good or the discharge pipeline is blocked, hydrogen in the indoor or localized closed space aggregation reaches a certain concentration, the external impact of open flame, lightning, or electrostatic discharge sparks, short-circuit overcharging or overdischarging and other unforeseen factors may form a fire or even an explosion potential hazard;

- Electronic equipment in the energy storage plant buildingEnvironmental humidity does not meet the national standard requirements, resulting in the failure of electronic equipment due to excessive humidity in the air, leading to fire accidents.

III. Our solutions

Complete quality certification system

Jiangxi Jian'an Fire Protection Technology Co., Ltd. is committed to pursuing high quality standards and technological innovation, and possesses a number of domestic and international quality certifications, including ISO9001 Chinese and British dual certification, ISO14001 environmental management system certification, ISO45001 occupational health and safety management system certification, as well as international certifications from Classification Society of China (CSC) and CE of the European Union (EU), which ensures the international competitiveness of its products. Meanwhile, the company's products have passed the certification of the Fire Protection Products Conformity Assessment Center of the Ministry of Emergency Management, which strengthens the performance and quality. As a state-recognized high-tech enterprise, Jianan Firefighting has also been certified as one of the "Specialized, Specialized, Specialized and New" small and medium-sized enterprises in Jiangxi Province, rated as one of the industry's "Top Ten Automatic Fire Extinguishing Enterprises" and awarded the Famous Trademark of Jiangxi Province, which highlights its leading position and brand influence in the field of automatic fire extinguishing. position and brand influence in the field of automatic fire extinguishing. These certifications and honors are the evidence of Jian'an Fire Protection's relentless pursuit of excellence.

Contact Us Now

- Service Hotline: 400-915-1190

- E-mail:1013086865@qq.com

- Fax: 400-915-1190

- Address:Banqiao Industrial Zone, Zhushan Town, Yushui District, Xinyu City, Jiangxi Province, China